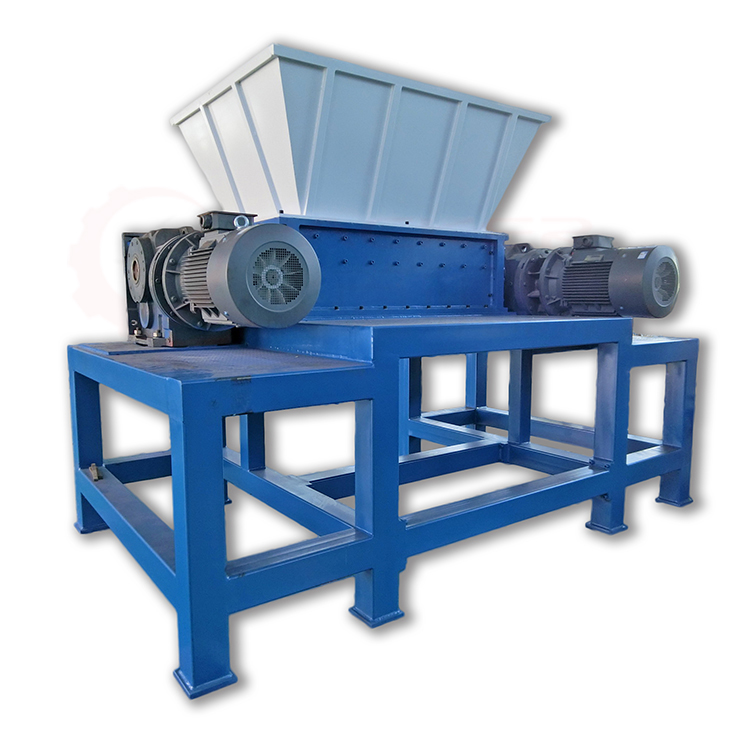

Plastic single shredder is used for materials that are highly resistant to fracture and thick. The rotors

of these single shaft shredder are made of wear-resistant alloy, which makes them smooth and have

a contour. When using abrasive or easily heated materials, such rotors will not overheat due to

the uniform distribution of heat generated by friction.

The working principle of a single axis shredder is as follows: the shredded material is fed into the

hopper through a hydraulic pre-press, into a rotating rotor, and the cutting tool is fixed on the rotor.

Materials can be loaded mechanically (using loaders or inclined conveyors) or manually. The press

then performs reciprocating motion, pressing the material onto the rotating rotor.

In this area, the waste has undergone initial destruction. Then cut the material into smaller pieces in

the cutting area. Afterwards, the crushed particles fall onto the sieve under the action of gravity, and

there are certain sized pores in the sieve, which determine the final fraction value. The fragments of

the material were proven to be larger than the size of the small holes and were sent for secondary

grinding. Wait a minute. Repeat these cycles until all processed materials are completely crushed.

As we have already mentioned, a single shaft (or single shaft) shredder is a universal type. But it is

most commonly used for recycling glass, thick walled plastic, film materials, glass, runners, paper, pallets, and pipes.

What benefits can purchasing our products

bring to you

The factory of Packer is located in Zhangjiagang (Jiangsu. China). We have more than 50 workers and our factory has 9000 square meters.

This plastic washing recycling production line is mainly used to recycle waste plastics such as automotive interior and exterior trim plastic parts, hollow packaging barrels, waste logistics trays, and home appliance shells made of HIPS/ABS/PP materials.

The factory of Packer is located in Zhangjiagang (Jiangsu. China). We have more than 50 workers and our factory has 9000 square meters.

This plastic washing recycling production line is mainly used to recycle waste plastics such as automotive interior and exterior trim plastic parts, hollow packaging barrels, waste logistics trays, and home appliance shells made of HIPS/ABS/PP materials.

Professional plastic recycling equipment solution provider to provide

you with one-stop product solutions