Nigerian Plastic Recycling Revolution: How Custom Line Design Drives Market Leadership

Release time: Thu 6, 2025 13:57Views: 34

Introduction

Nigeria generates 2.3 million tons of plastic waste annually (African Environment Agency 2024), yet 85% of recyclers struggle with imported European equipment mismatches:

- 42% faster wear rates when processing local high-contamination PET flakes

- Grid electricity costs exceed ₦140/kWh with poor peak/off-peak management

PACKER, in collaboration with Lagos State University Polymer Labs, delivers context-specific solutions blending global tech with African realities...

Section 1: Three Survival Challenges for Lagos Recyclers

Challenge #1: Desert-Ready Equipment Failures

- European twin-screw extruders average 6.7 days/month downtime during Harmattan seasons (₦2.8M quarterly losses)

Challenge #2: Cost Calculation Illusions

- Promised energy consumption of 620kWh/ton hits 840kWh in Kano State field tests

Challenge #3: Certification Complexities

- Local PCR content fluctuates ±18% against Walmart's 30% requirement

Section 2: Three-Step Customization Engine

Step 1: Nigerian Waste DNA Mapping

- Raw Material X-Ray**: Analyzes 200km radius plastic composition (e.g., 33% pesticide container shock finding in Kano)

- Informal Collection Heatmaps**: Identifies high-purity waste hotspots

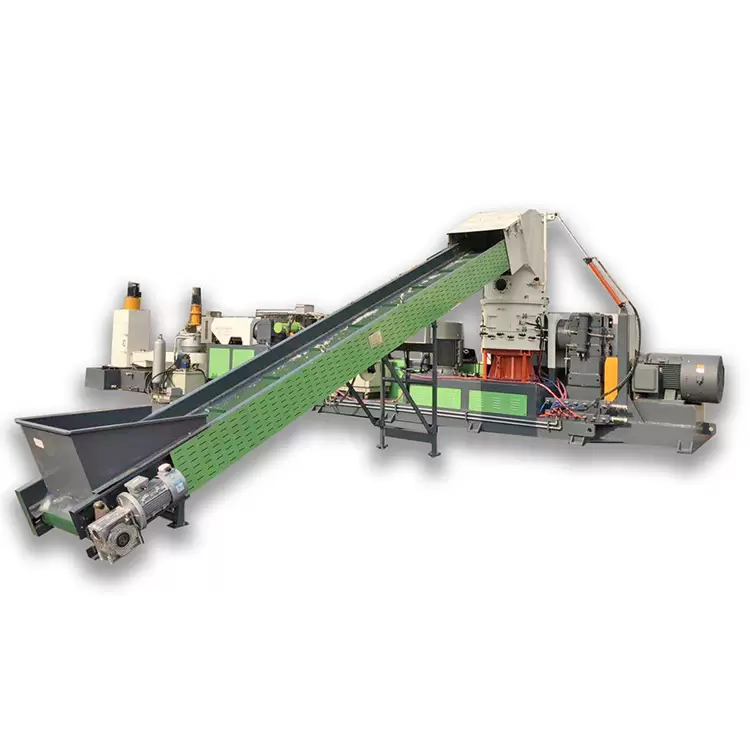

Step 2: West Africa-Optimized Configurations

- High-Durability PET Lines:

→ Dust-sealed friction washers (sandstorm-proof)

→ Tungsten carbide-coated screws (processing glass-fiber contaminated flakes)

-Agricultural Film Solutions:

→ Cyclonic pre-separators (soil/stone removal)

→ Dual-path melt filtration systems

Step 3: Dynamic Cost Simulation

- Inputs: Diesel generator ratios, NAFDAC certification timelines, customs clearance fees

- Outputs:

→ Naira fluctuation stress tests

→ Minimum viable capacity thresholds (with equipment leasing options)

Case Study: Kano State Transformation

Client Profile:

Bature Recycling Works (PET flake processor expanding into agri-film recovery)

Customization Journey:

▸ Market Intelligence:

- Discovered 24% annual growth in PE agricultural film waste with zero local processors

- Detected herbicide residues requiring specialized treatment

▸ Tailored Line Retrofit Plan ($87,000 Investment):

→ Existing crusher retained (₦34M savings)

→ Added corrosion-resistant hot wash tank + three-stage activated carbon filtration

▸ Energy Optimization:

Implemented "Night Shredding/Afternoon Pelletizing" schedule aligning with ₦158/kWh peak rates

Operational Gains (12 Months):

→ PE pellet ash content reduced from 1.8% to 0.3%

→ RecyClass Africa pilot certification acquired

→ Secured 1,200MT/yr contract with French agribusiness leader

Founder's Insight:

"This system understands West African plastics better than our local engineers!" – Aliyu M., Bature Recycling

Conclusion

With 217 global partners and our Lagos-based technical squad, PACKER bridges the gap between European over-engineering and African makeshift solutions.

▶ Get Your Africa-Specific Toolkit

Input your recycling focus to receive:

→ West African contaminant distribution maps (heavy metals included)

→ Kano/Abuja top recyclers' equipment analysis