Decoding Efficiency: PET Washing Line Cost-Slashing Playbook from a Supply Chain Veteran

Release time: Thu 6, 2025 12:01Views: 36

Introduction:

As global demand for recycled PET surges at a 6.8% CAGR (Grand View Research, 2023), Asian processors grapple with profit margins below 8% (China Circular Economy Association). Yet savvy players are unlocking hidden efficiencies in the most unexpected corners of their washing lines...

Chapter 1: The Invisible Cost Traps in PET Washing

Three stealthy profit killers dominate typical Asian recycling workshops:

- Fragmentation Inconsistency

-> Size variance >12mm in conventional shredding leads to 25% longer friction washing cycles

- Ferrous Contamination Fallout

-> A single Φ3mm metal shard can seize bearings, triggering $2,800+ unplanned downtime

- Labor Dependency Quicksand

-> Manual pre-sorting consumes 35%+ of OPEX, with 40% workforce turnover paralysis

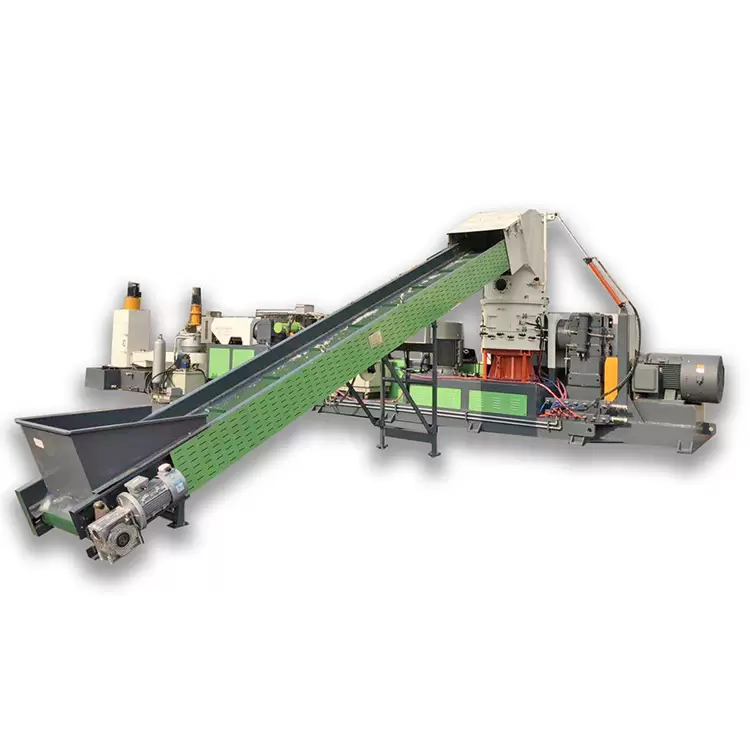

Chapter 2: Battle-Proven Efficiency Arsenal

Strategy #1: Homogenization Through Intelligent Shredding

-> Two-Stage Shredding System (Co-developed with Zhejiang equipment leaders):

Stage 1: Precision cutters target bottle cap/body joints

Stage 2: Dynamic screen mesh calibration (±2.8mm tolerance)

-> Result: 23% washing cycle acceleration (Guangxi trials)

Strategy #2: Ironproof Defense Grid

-> High-Gauss Magnetic Separators:

1,200+ Gauss strength captures ≥Φ1.5mm ferrous debris

-> Auto-Purging Metal Detectors:

Audible alarm + diverter valve activation

Strategy #3: Workforce Multiplier Tactics

- Ergonomic Pre-Sorting Conveyors:

Angled chute enables 150% faster inspection

- Blade Life Radar System:

Predicts blade wear via amperage monitoring

Chapter 3: Thailand Case Study - From Red to Black

Client: Sunrise Recycling (Chiang Mai)

Pre-Optimization Challenges:

- $9,200/month metal-related rework costs

- 53% labor hours wasted on QC

Post-PACKER Results:

-> Metal contamination complaints: 100% elimination

-> Fragment compliance rate: 93% → 99.2%

-> Labor hours: 2,840/month (-40%) → $10,500/quarter saved

Client Testimonial:

"This isn't just machinery – it's a profit guardian angel." – Mr. Somchai, GM

Conclusion & CTA:

PACKER bridges 57 ISO-certified equipment innovators with recyclers across Asia.

Get Your Free ROI Simulator:

Input monthly capacity to receive:

-> Customized cost-saving roadmap

-> Southeast Asia retrofit case bank

-> Supplier audit checklist (PDF)