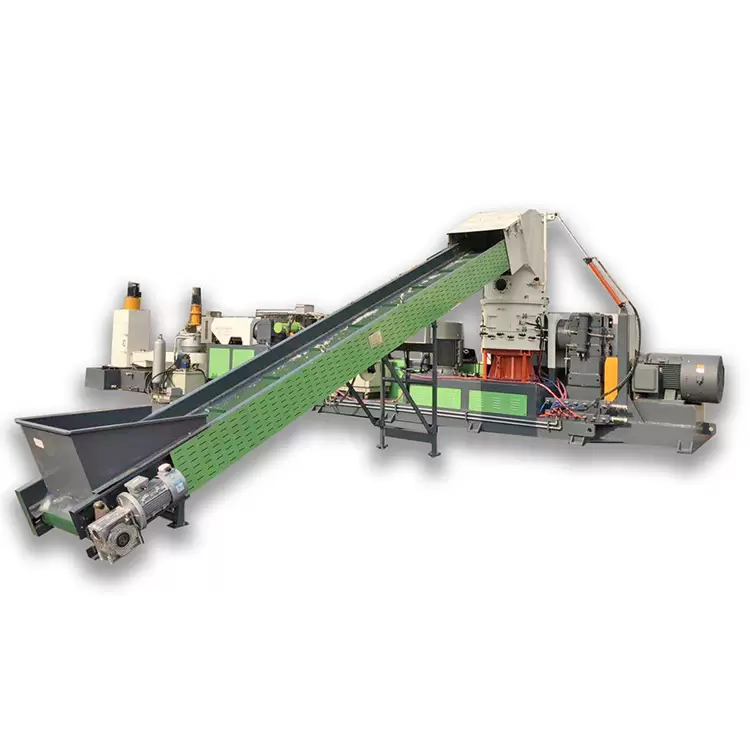

From Waste Drums to Profit Engines: How Small-Scale HDPE Recycling Lines Can Transform Your Business

Release time: Thu 6, 2025 11:46Views: 37

Introduction:

With 4,800+ tons of HDPE waste generated daily across Southeast Asia (ASEAN Environment Agency), small recyclers face critical bottlenecks:

- Energy consumption averaging 780kWh/ton – 28% above global benchmarks

- Metal contamination dragging pellet prices below $0.52/kg

PACKER’s down-to-earth HDPE solutions, co-developed with Asian equipment partners, are rewriting the rules...

Section 1: Three Survival Challenges for SME Recyclers

Challenge #1: The Midnight Breakdown Nightmare

- Metal cap fragments trigger extruder shutdowns 2-3 times quarterly ($6,500+/incident)

Challenge #2: The Electricity Bill Enigma

- Peak-hour rates consume 55%+ of power budgets

Challenge #3: The Certification Barrier

- Basic lab setups require $22,000+ upfront investment

Section 2: Practical Solutions for Real Workshops

Solution #1: Ironclad Metal Defense

① Magnetic Guardian System

- Overhead suspended magnets capture ≥ɸ2mm ferrous debris (lids/rings)

② Dual-Screen Quick Swap

- 80-to-120 mesh filtration flexibility

Solution #2: Smart Energy Hacks

- Peak/Off-Peak Dashboard: Visualizes time-based kWh costs

- Nightshift Optimization: Stores pre-heated materials during blackouts

Solution #3: Affordable Quality Control

- 3-Layer Vibrating Sieves: Adjustable 10-30 mesh screening

- DIY Test Kit:

→ Melt Flow Index tester (±2% accuracy)

→ Color-matching swatch cards (free with equipment purchase)

Section 3: Vietnam Case Study - The Can Tho City Turnaround

Client Profile:

Chan’s Recycling Workshop (Family-owned, 300MT/month capacity)

Pre-Upgrade Pain Points:

→ 4-6 metal-related breakdowns monthly

→ Daytime energy costs ate 68% of margins

PACKER’s $48,000 Retrofit Package:

✔ Hardware Upgrades:

- Front-end magnetic separator + metal detector

- Thermal buffer silo for off-peak pre-heating

✔ Process Reengineering:

- Adjusted screw speeds for stable night operations

- Graded sieving boosted pellet uniformity to 92%

12-Month Results:

→ Zero unplanned stoppages

→ 73% off-peak energy utilization → $19/ton cost drop

→ Pellet pricing up 23% (secured local toy manufacturer contracts)

Owner’s Verdict:

"These aren't machines – they're profit-protecting bodyguards!" – Mr. Tran Van Hung

Conclusion:

We speak the language of SME survival: No flashy specs, just hardcore ROI. PACKER bridges Japanese precision and Chinese pragmatism to deliver battle-tested solutions.

▶ Download "Budget-Smart Upgrade Blueprint"

Select your monthly capacity to access:

→ Equipment pairing guide (incl. refurbished options)

→ Vietnam/Philippines operation cost breakdowns